Week8

Computer-Controlled Machining

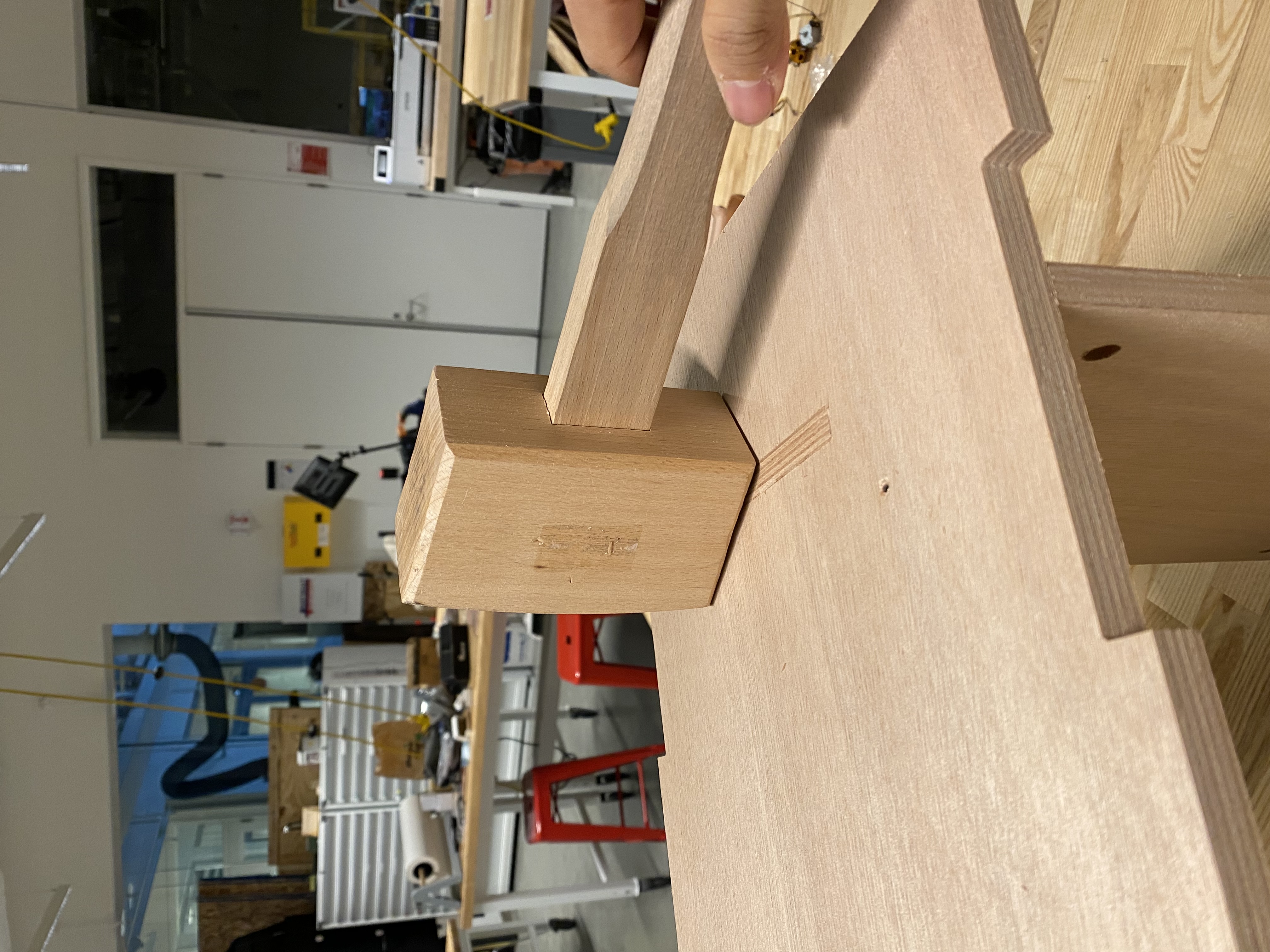

Designing a ‘Keep-in-Mind’ Box

What if we could put our ‘thoughts’ or ‘concerns’ or even ‘delights’ in a box,

and somehow the box knows what’s inside?

[Process]

[Design]

I started off right away in CAD, but usually I start with paper prototyping. I stacked some IKEA boxes for this project, but as I was running out of time, I had to work directly on CAD. I decided to make a box that can have a playful interaction with the user.

[Production]

This is the first furniture I made ever, and if I’m gonna make this I wanted to use it in my apartment.

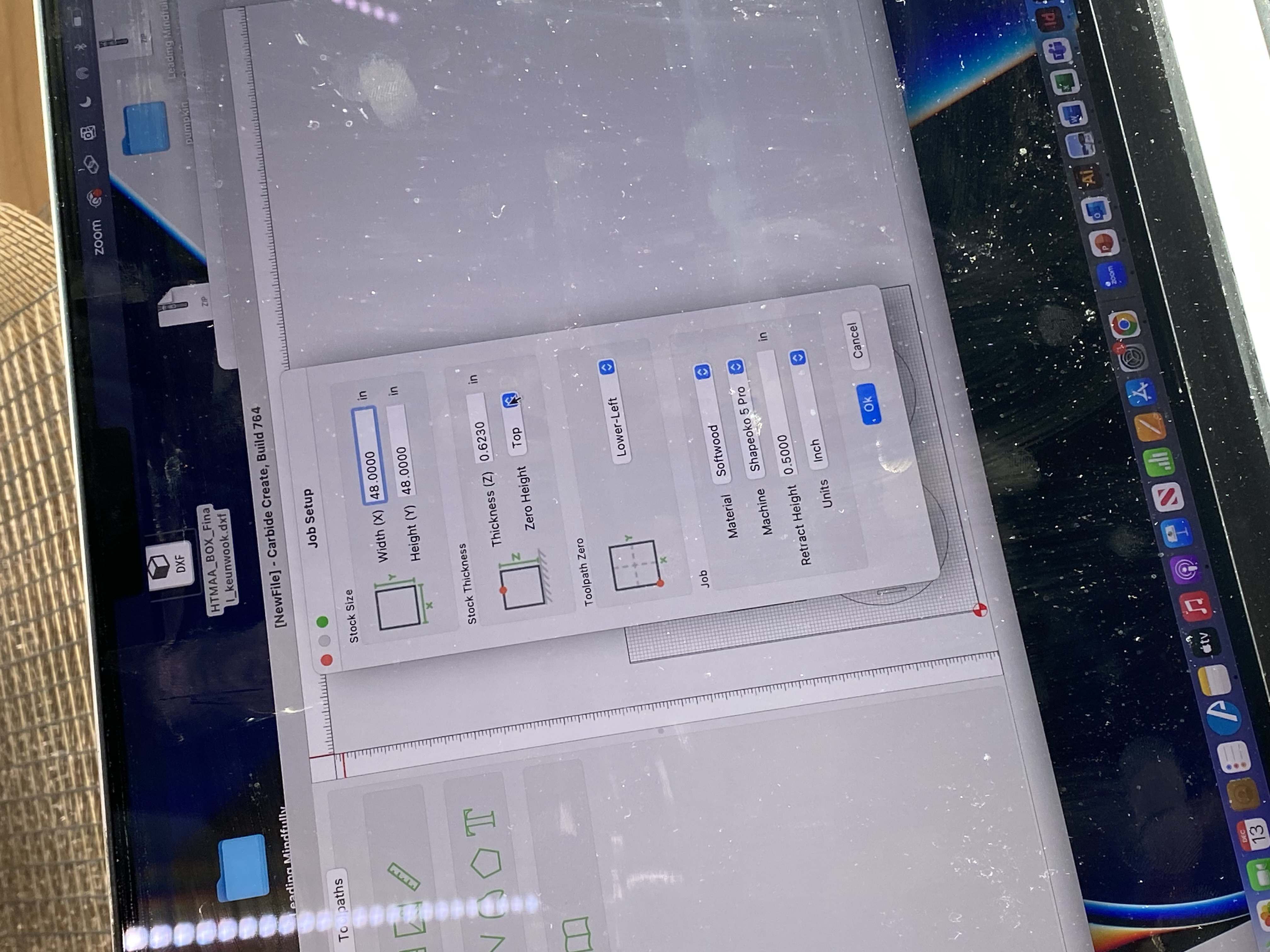

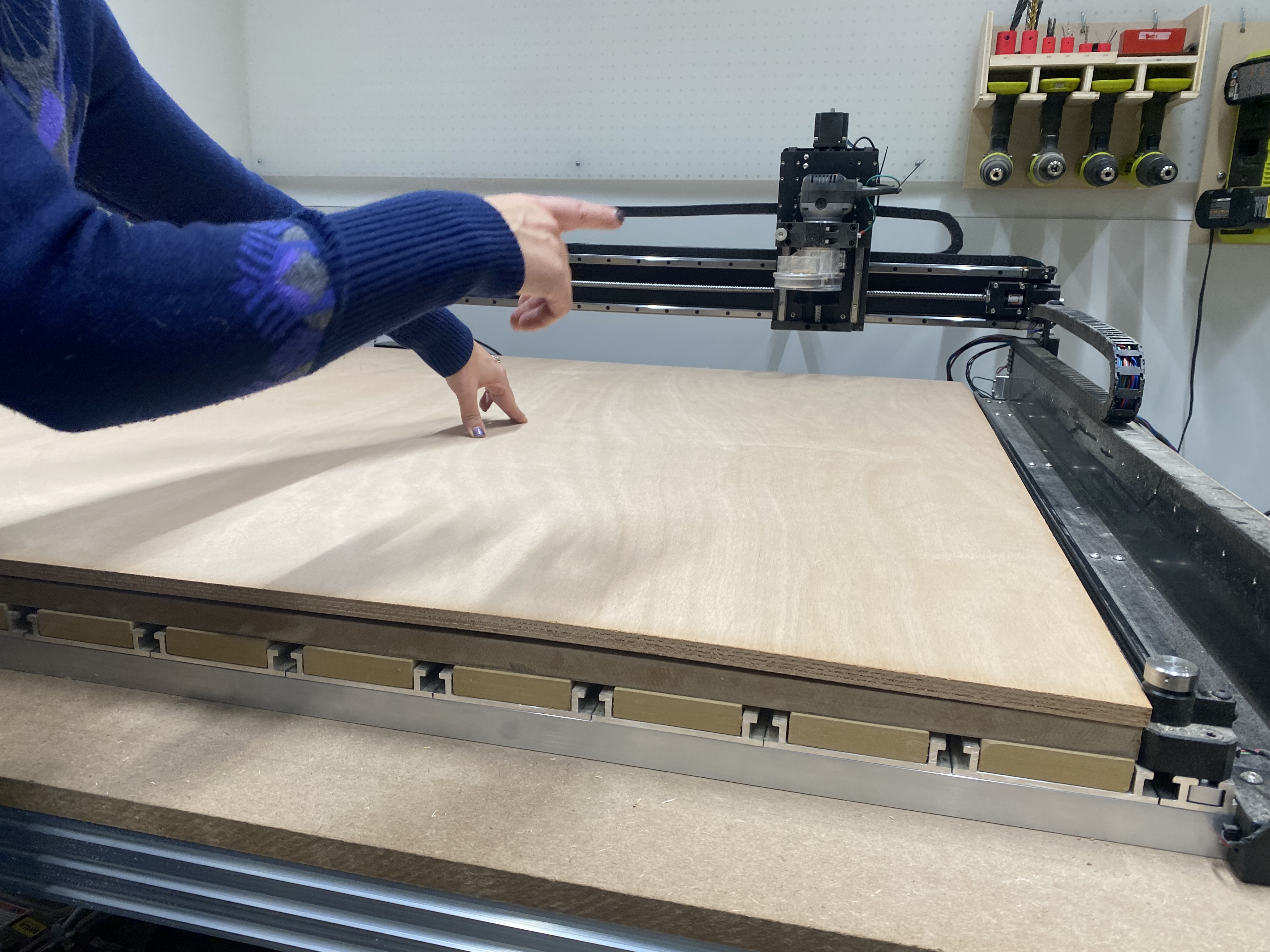

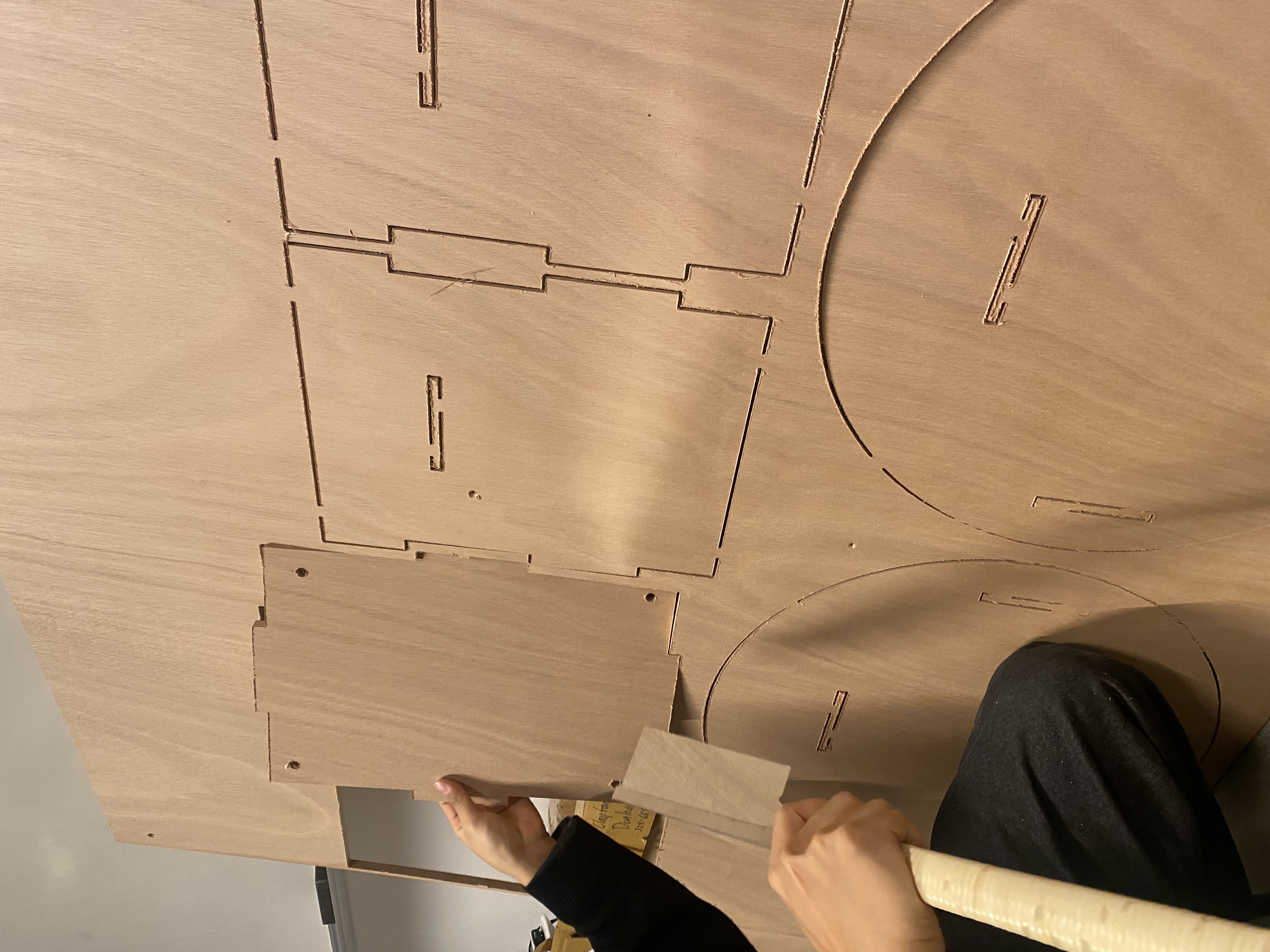

So I really didn’t want to use the OSB, and started off this project with searching for better woods. Josh helped me with finding the wood shop and delivering the wood to the REEF. As the Harvard CNC machine can handle 4X4 maximum, I bought 4X8 mahogani plywood piece and cutted it into half.

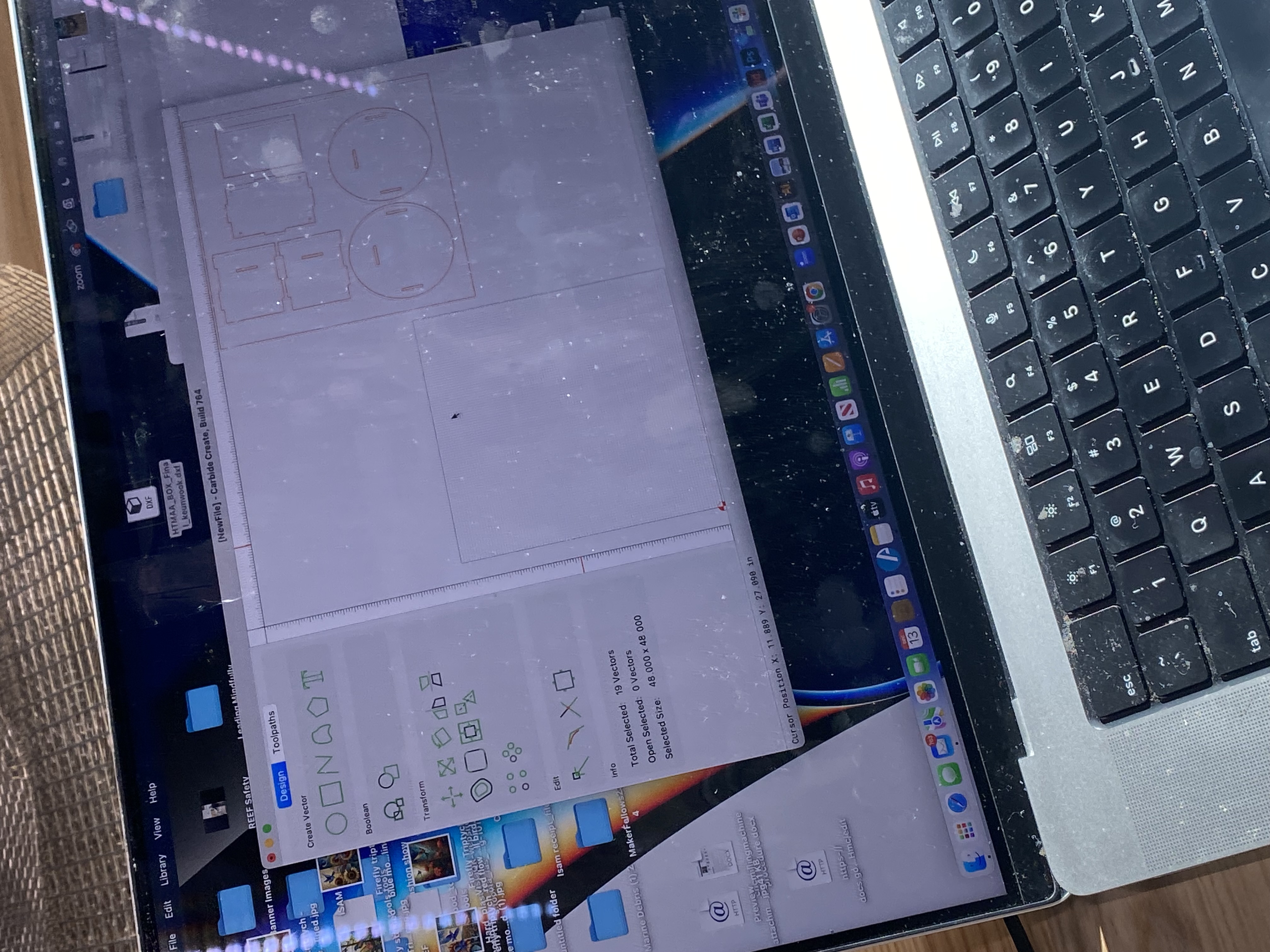

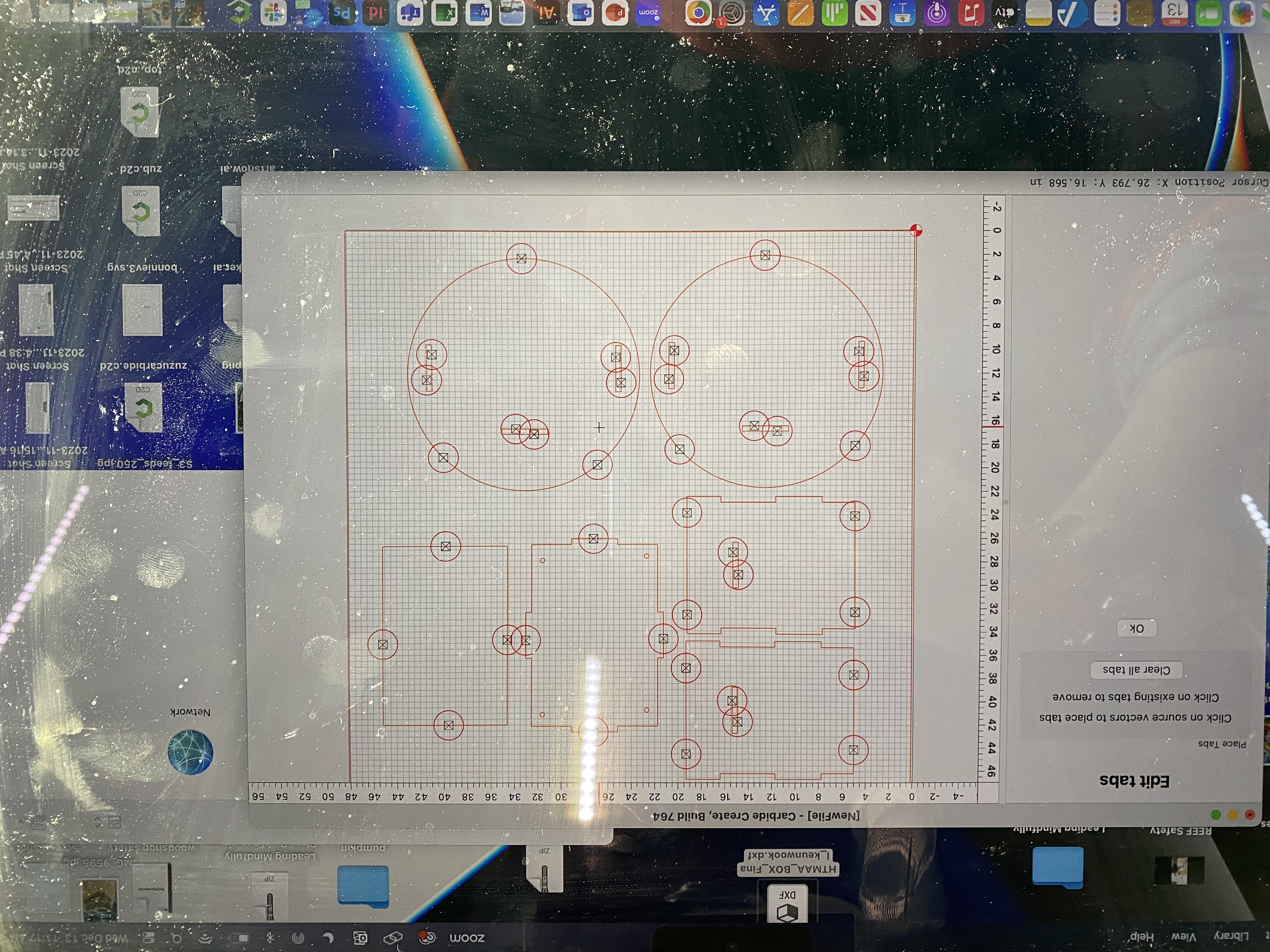

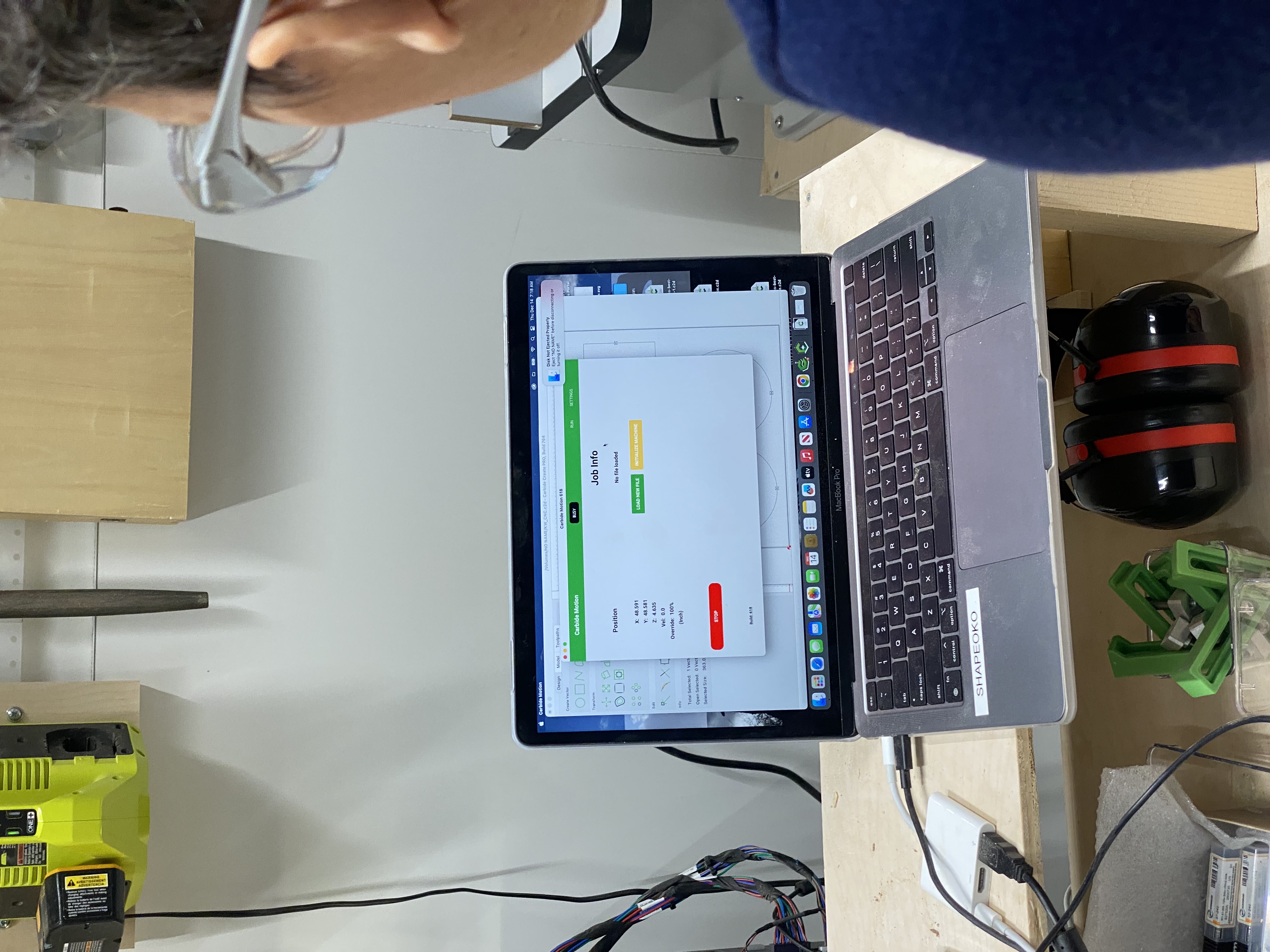

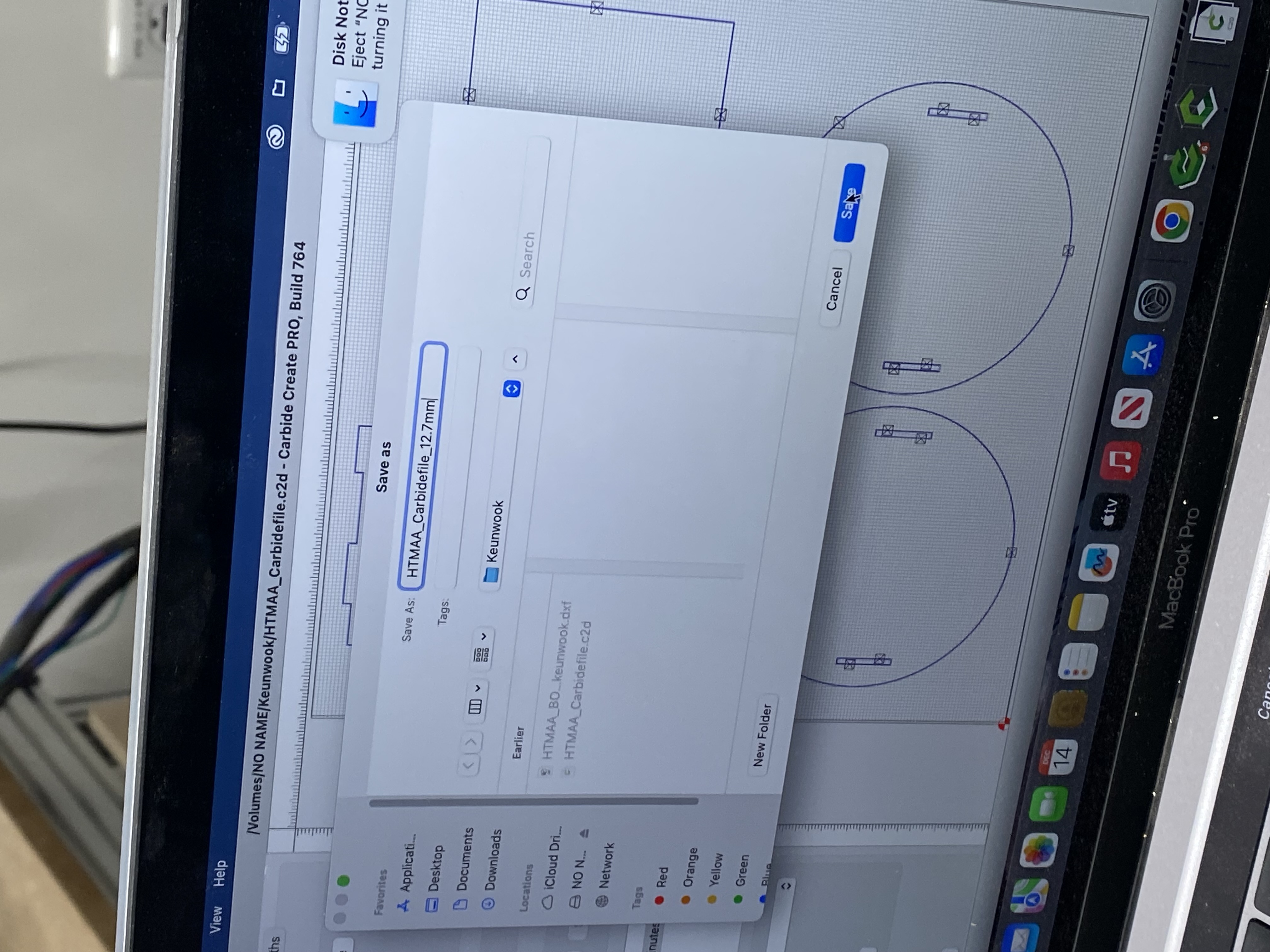

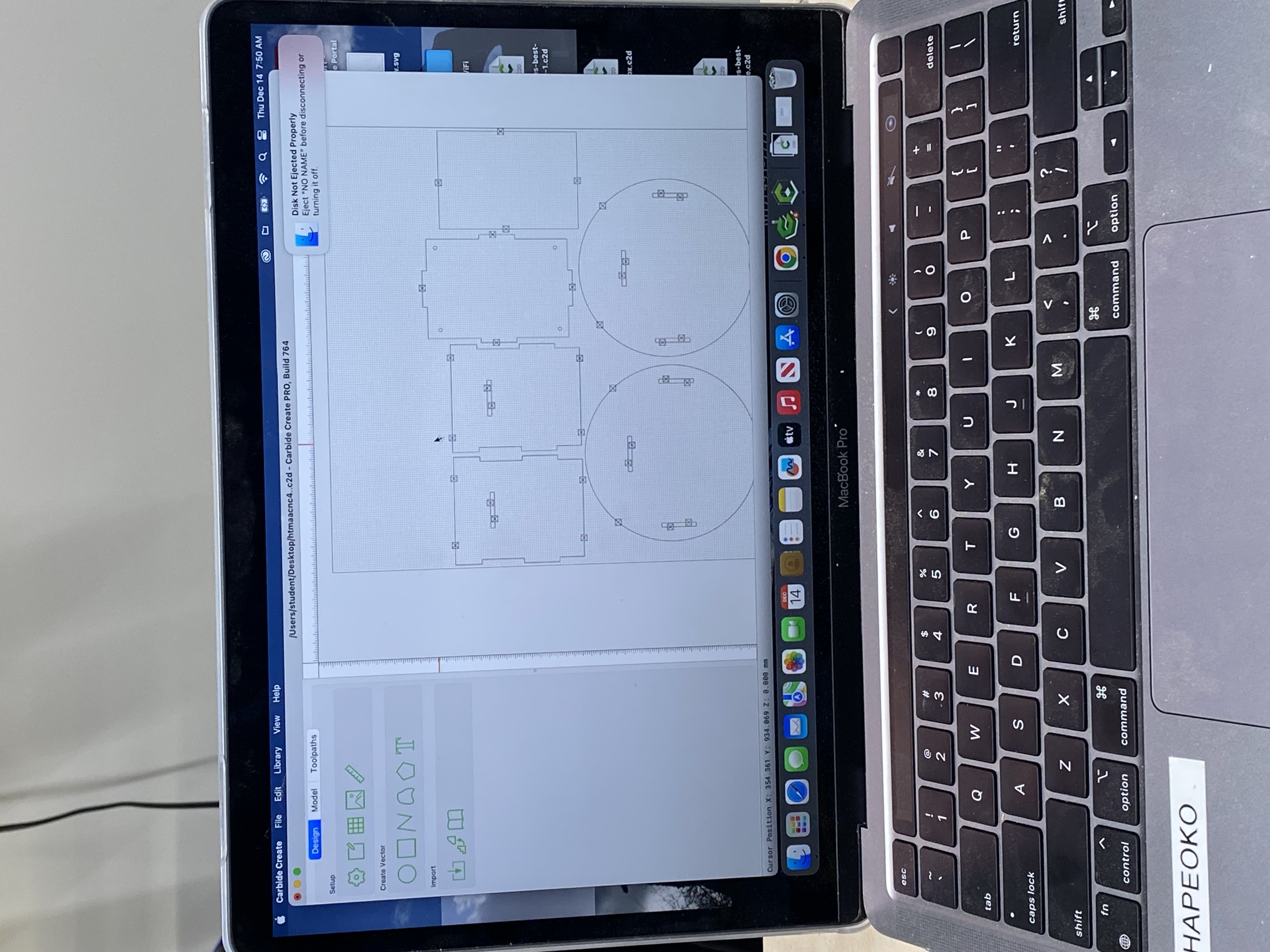

When I came to REEF, Chrstine walked me through how to set up the file with Carbide Create

These are for holding the part even when the toolpath cut throguh the material.

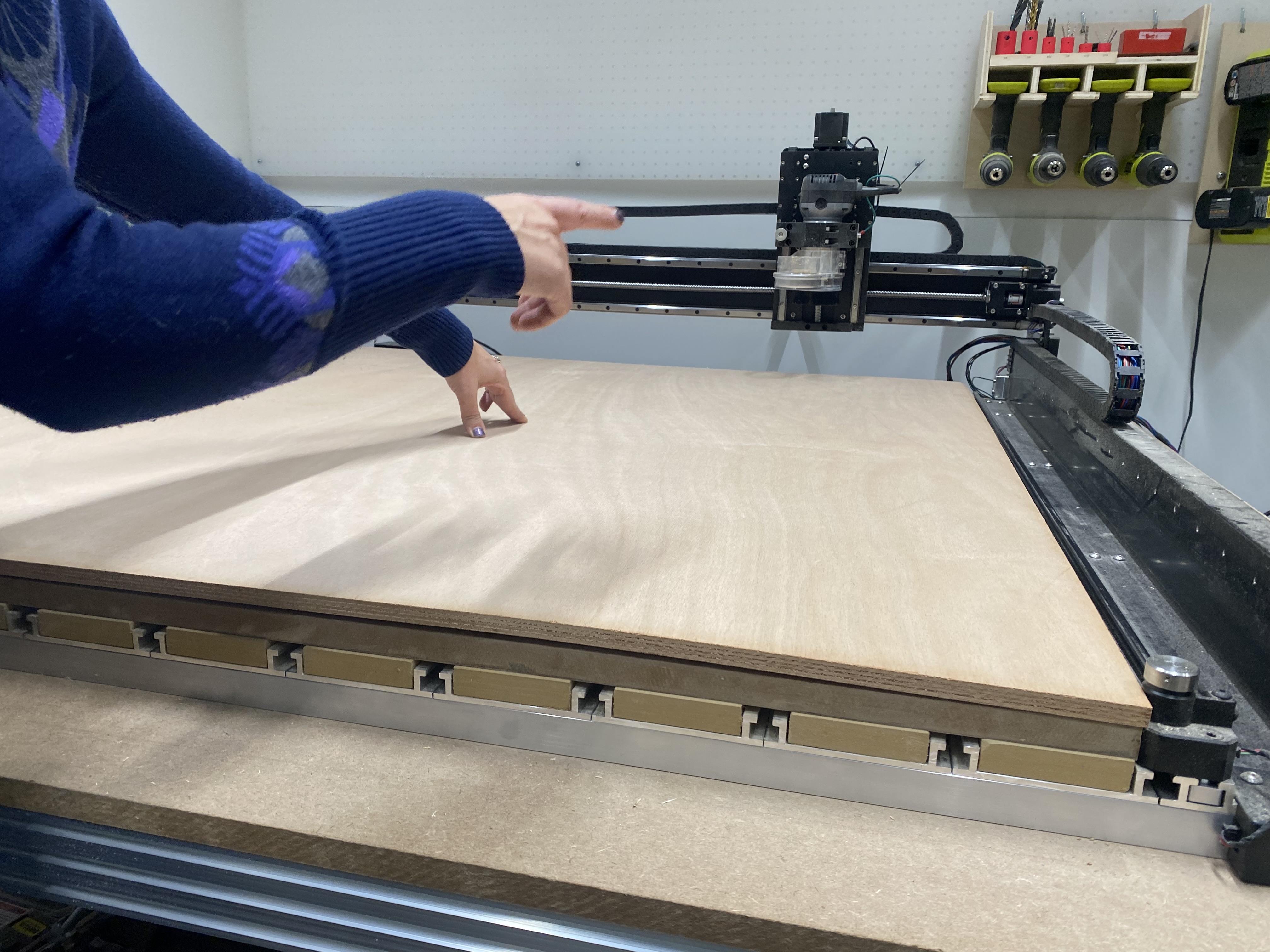

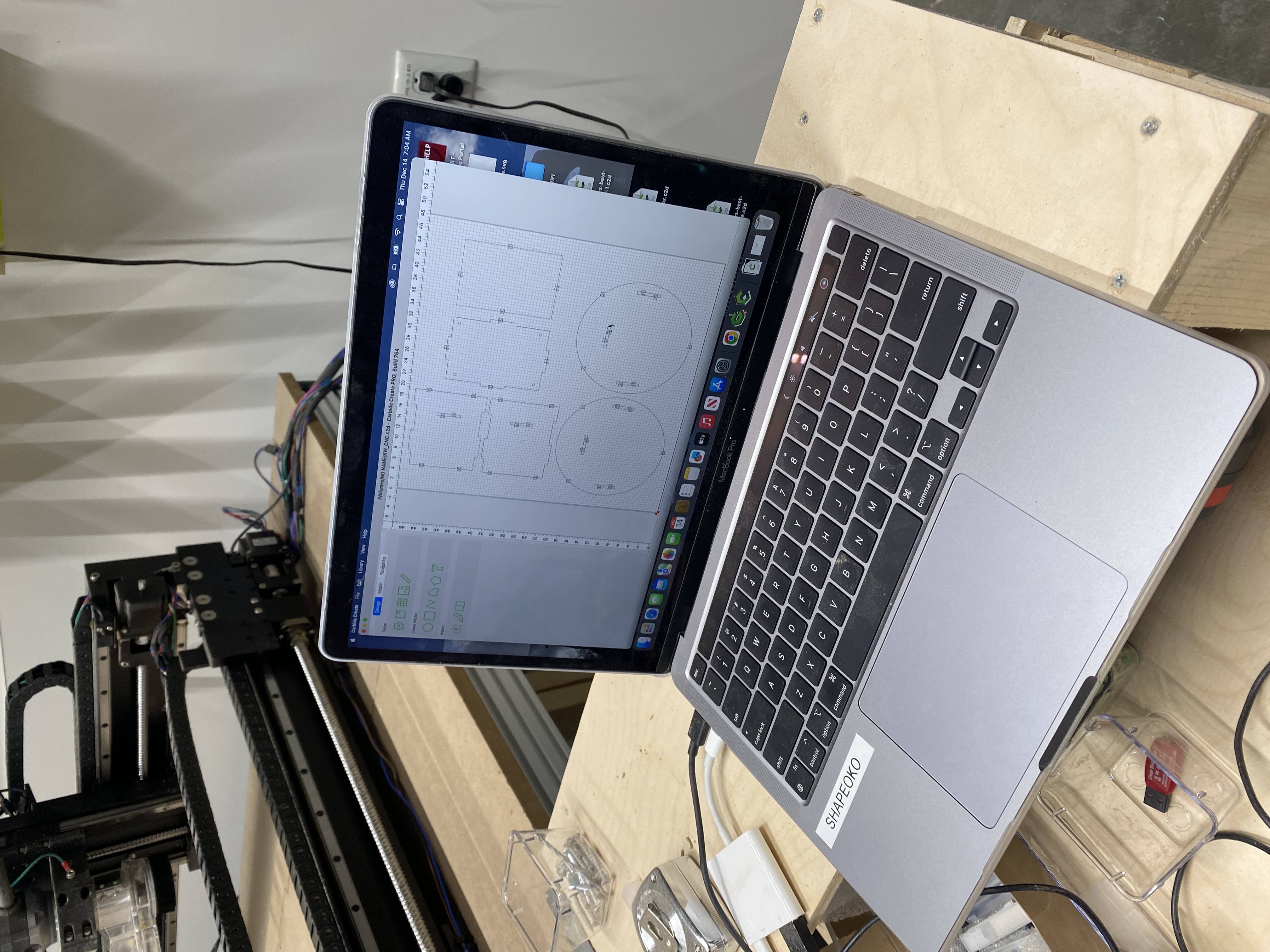

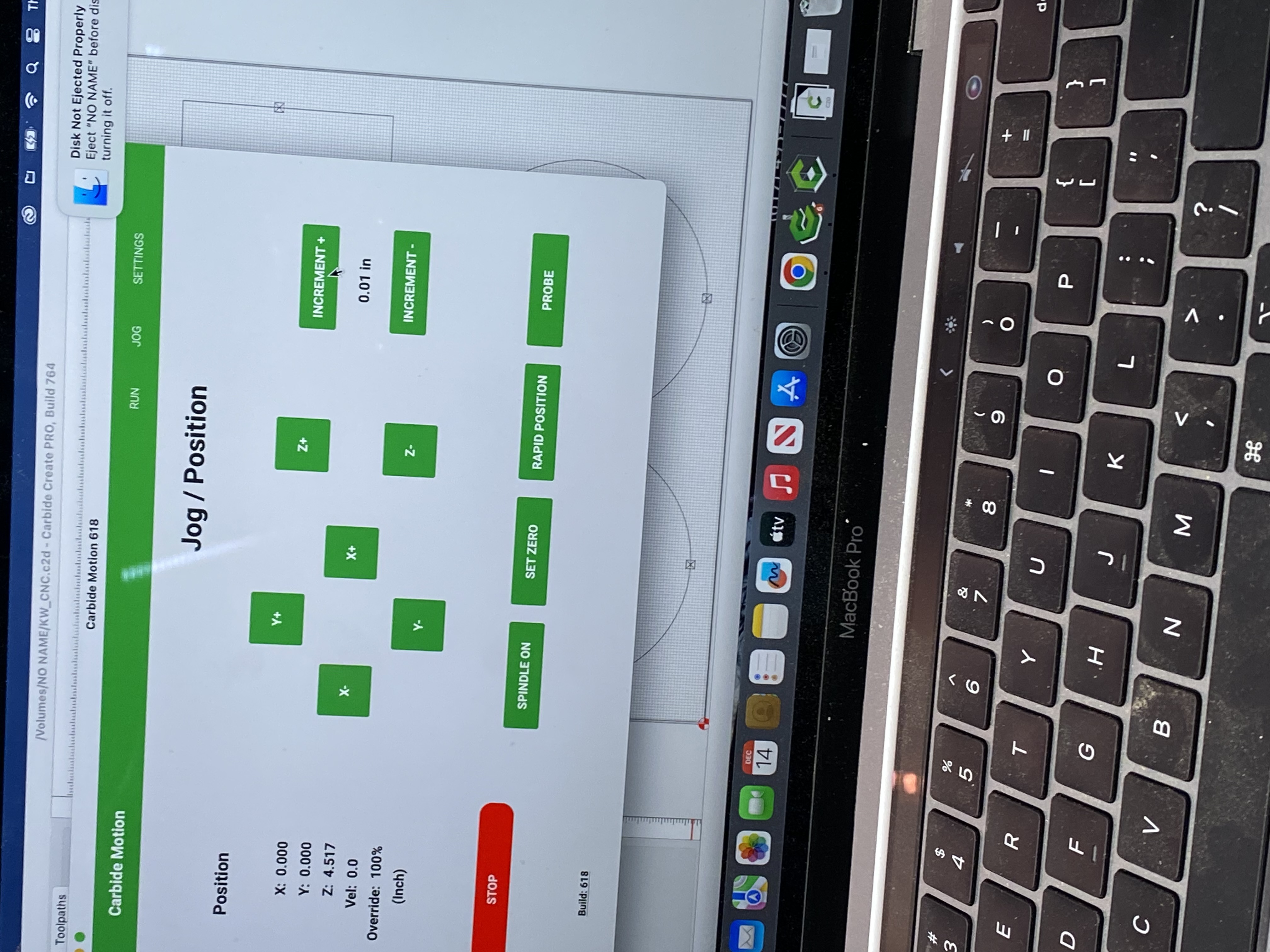

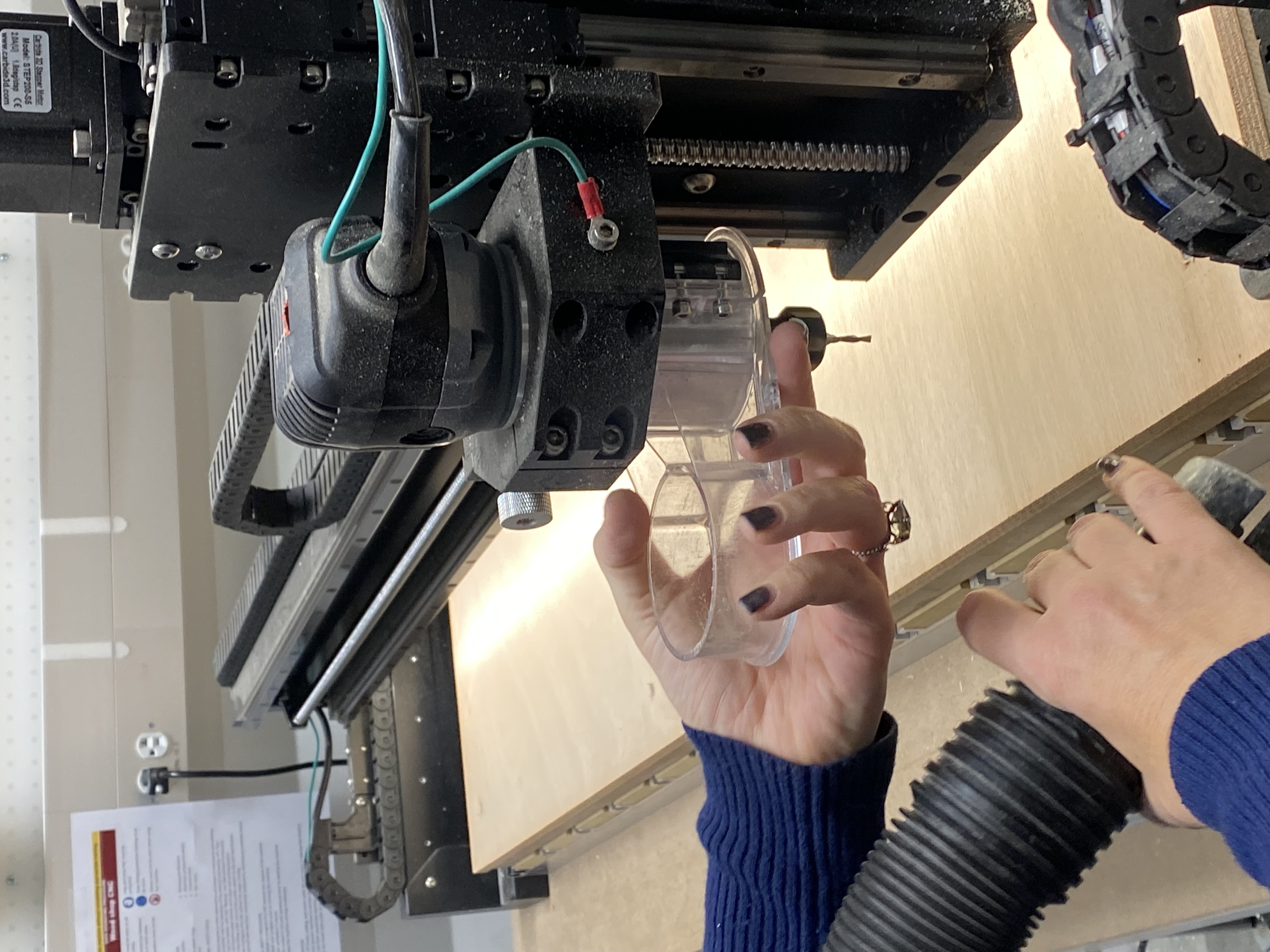

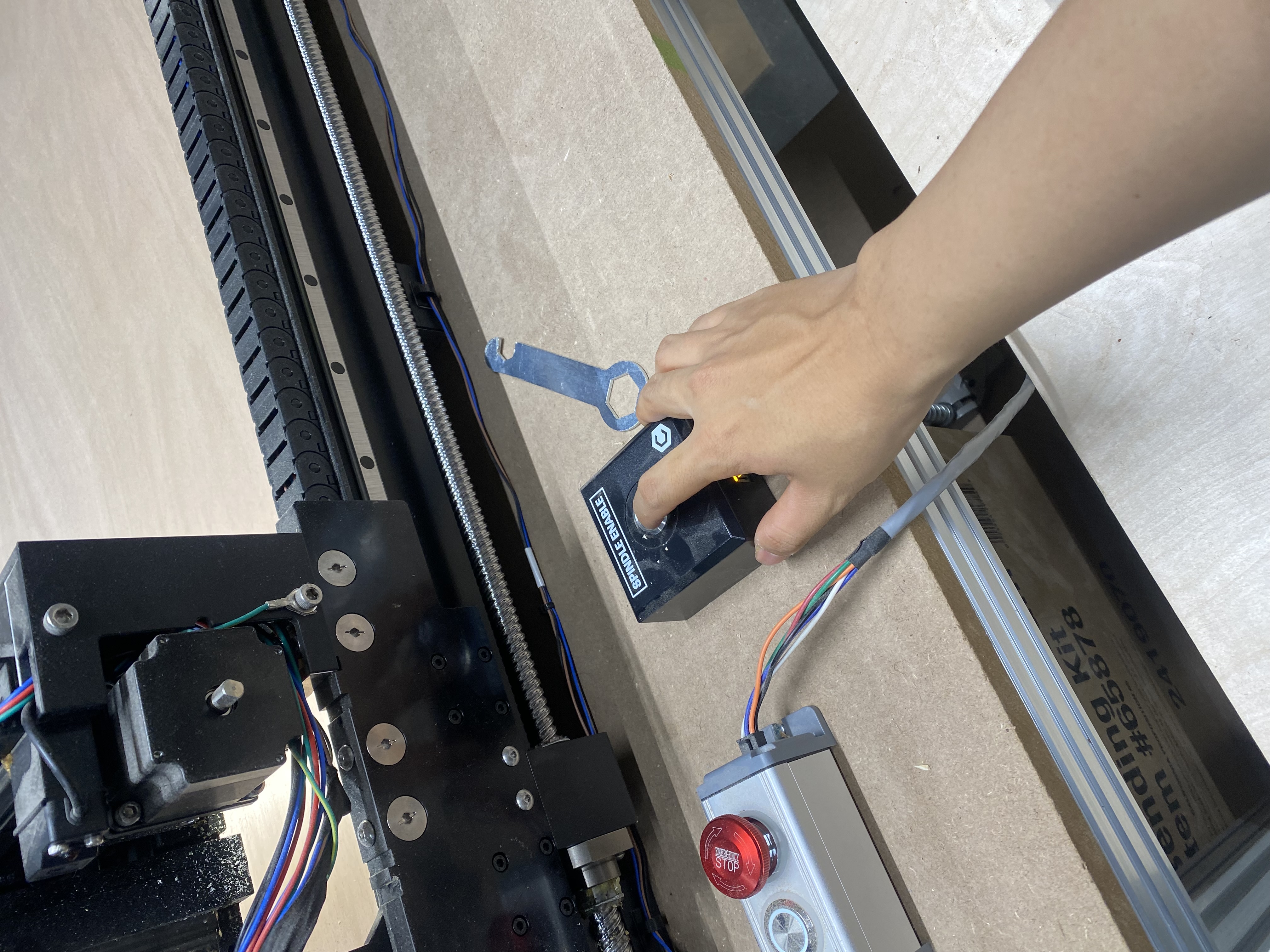

After finishing setting up in the Carbide Create, Christine walked me throguh how to use the machine

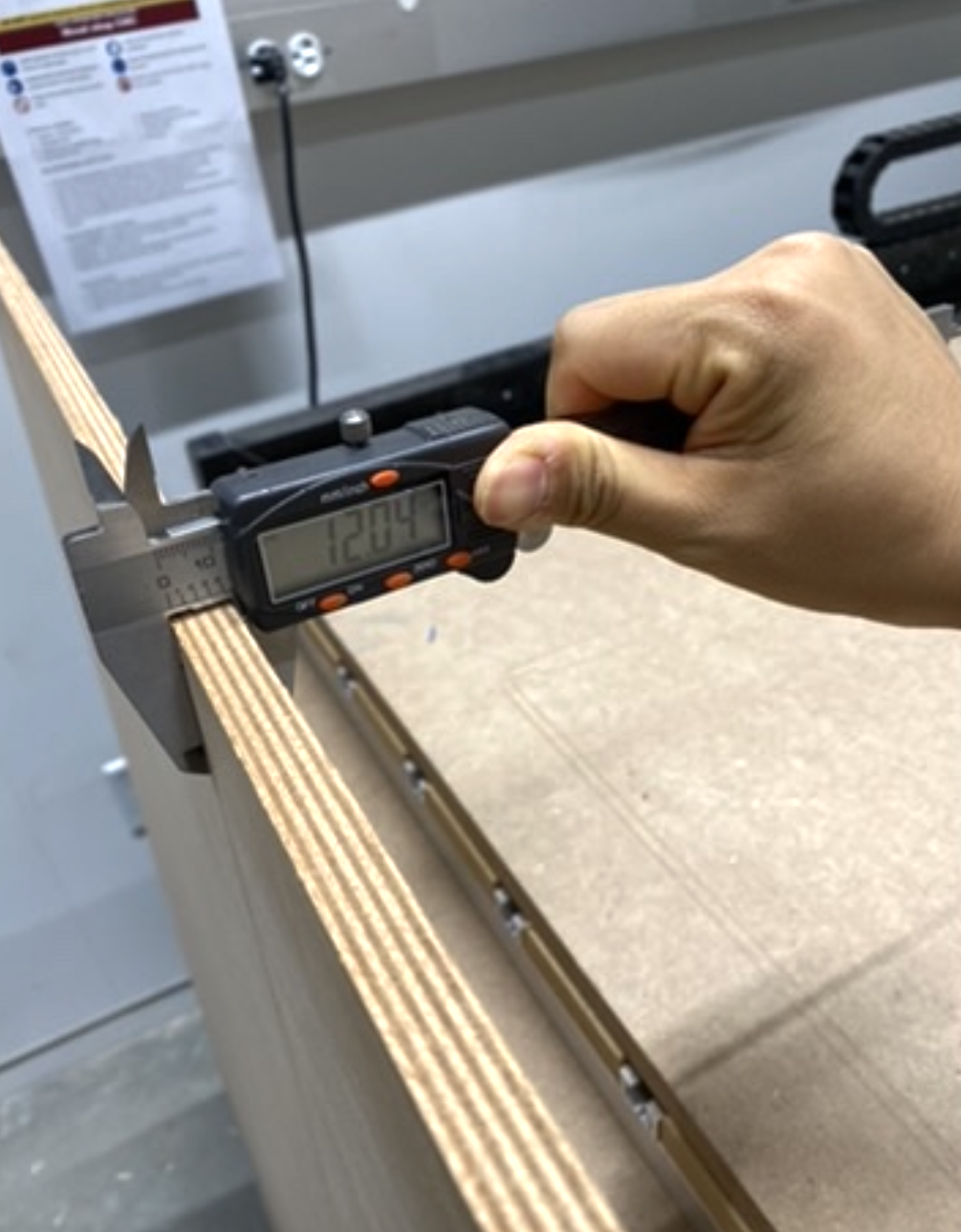

I 3D modelded the box based on 11.8mm - as I measured it before, however, as it is wood, eventhough I bought a high quality one, can not be identical in terms of thickness

Christine explaining why it’s important to keep the wood flat - and how to do it. Then connected the machine to the computer

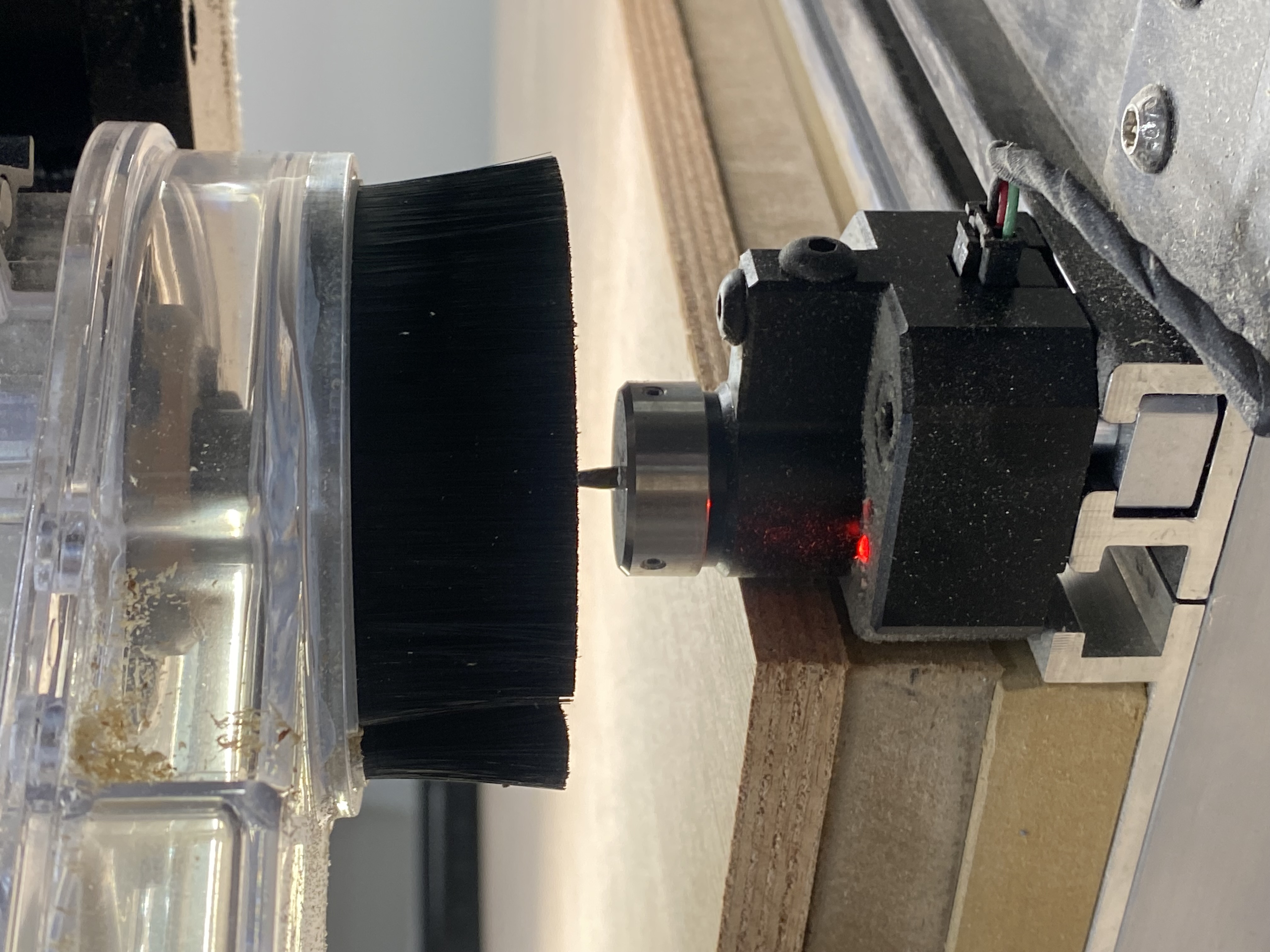

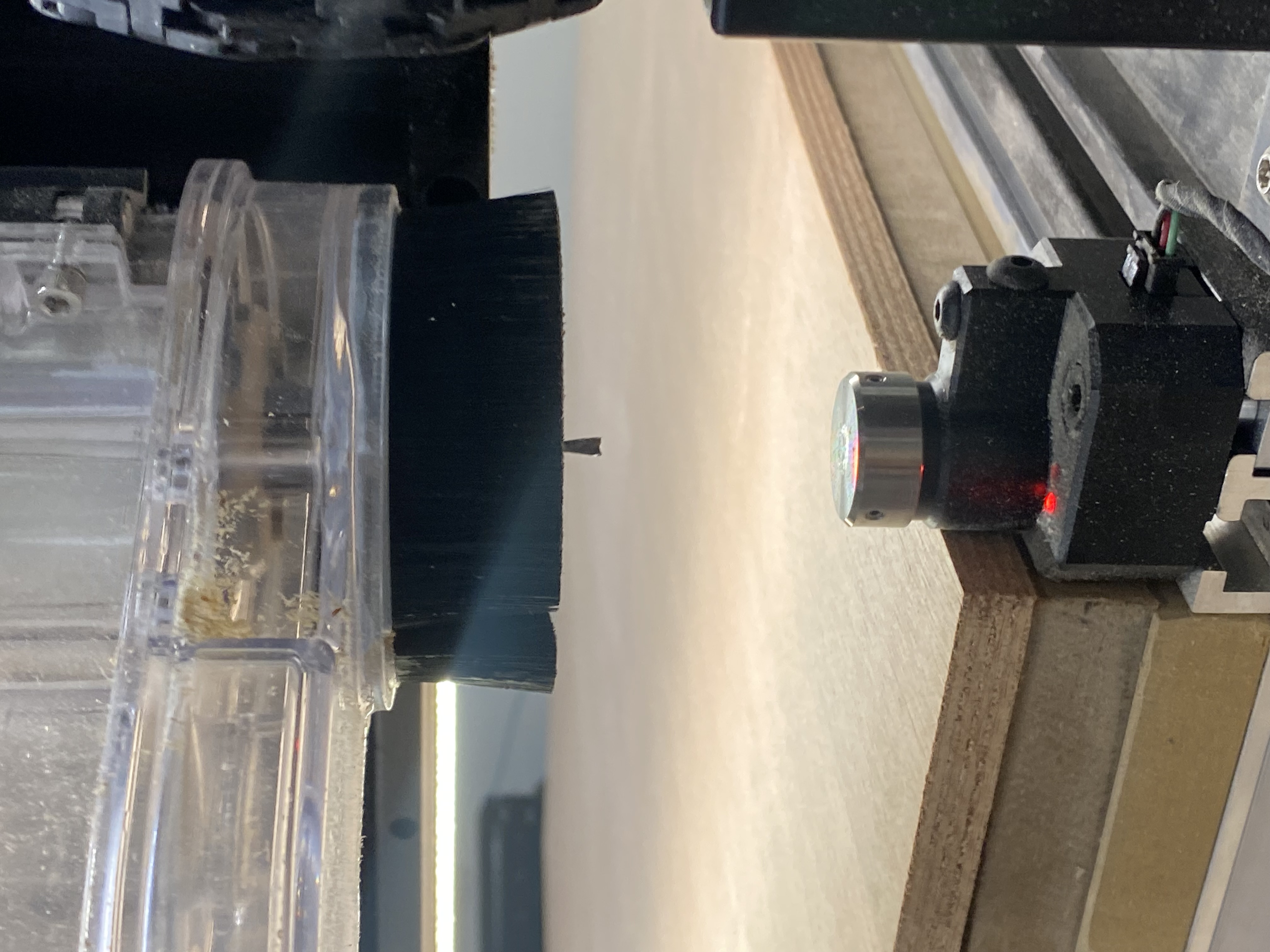

Z axis calibration

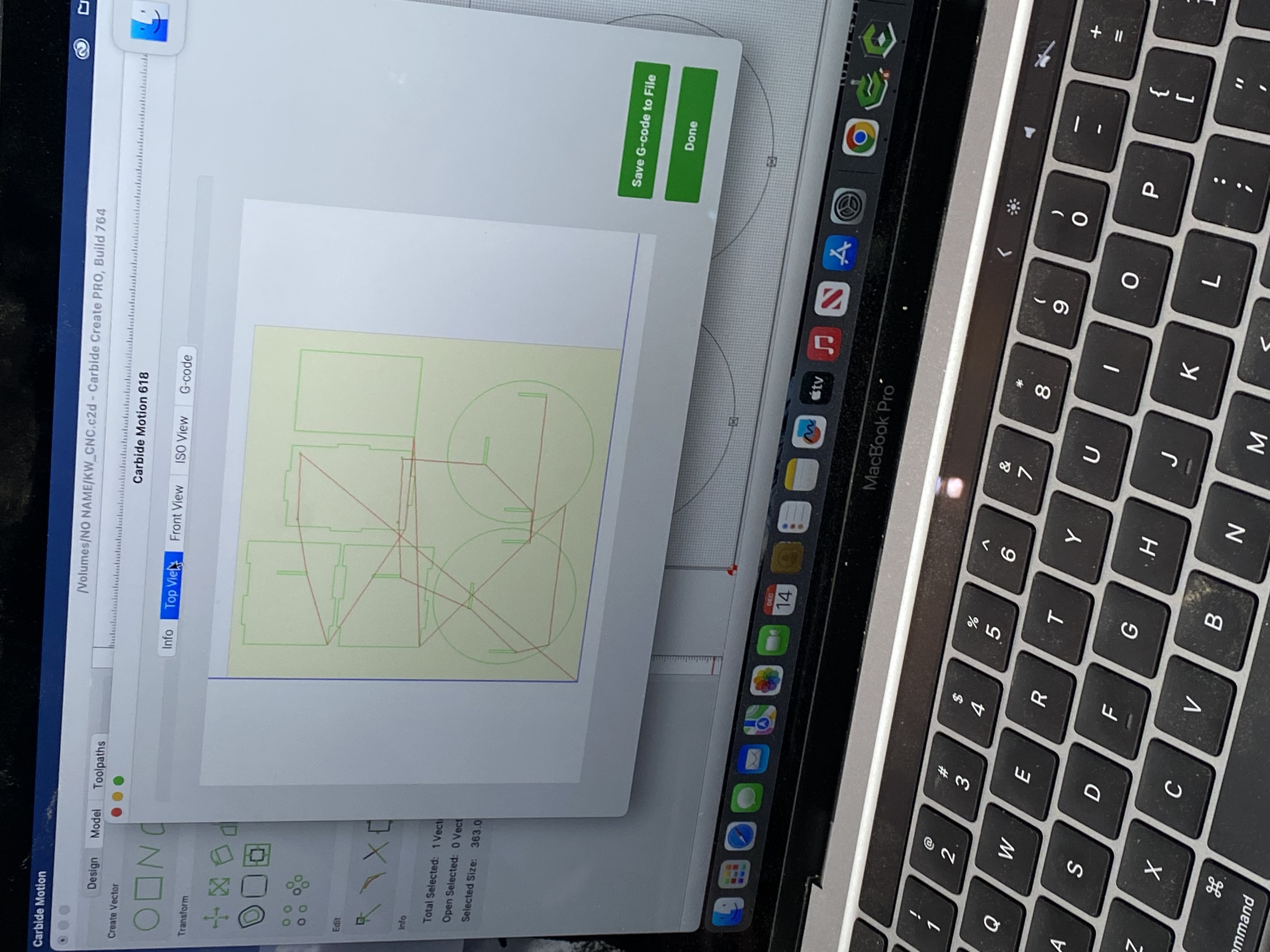

Running simulation

It moves like this when the user put something inside it.